Six Benefits of High Precision in Plastic Injection Molding

Have you found yourself questioning the importance of high precision molds and whether they would make a difference to your end product? The reality is that high precision in plastic mold making, or a lack thereof, can affect your business in numerous ways. High precision in mold making is a crucial factor to consider when […]

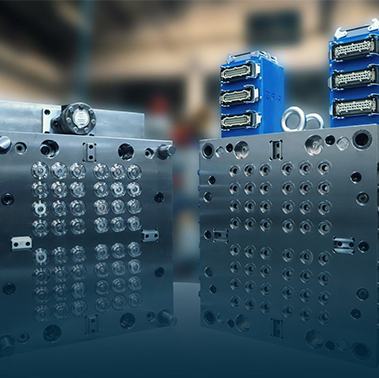

How to Choose the Right Plastic Mold Manufacturer

Choosing the right mold manufacturer for your plastic products is a crucial decision. The manufacturer you select can significantly impact the quality of your production. In fact, making an informed choice regarding your plastic mold provider is paramount in ensuring your products meet your standards and those of your clients. Here, we will walk you […]

Navigating the Challenges of Plastic Producers in Nigeria

Meta Description: Financing Challenges Business owners, new or established, rely on banks to finance their operations, but access to credit remains a persistent challenge in Nigeria. In this country, banks do not readily lend money to entrepreneurs. Financial institutions often impose stringent lending policies and high-interest rates, ranging from 25% to 40%, making it difficult […]

Nine Questions every client should ask before picking Mold Maker partner

When you’re getting ready to begin the injection molding process, the first choice you make—and one of the most crucial decisions—is which plastic mold manufacturing partner you’ll select. The partner you choose should, of course, deliver on all your mold requirements—but they should also prototype your part, help you with part design adjustments, warranty their […]

Mold Trial Production Operational Manual

Load the mold and: As per the material’s property and the mold tool size to choose the appropriate mold temperature controller to heat up the needed mold temperature. We need to check again all the movements of the mold after the mold temperature is up. If cycle time is too short, ejector pins will break […]

IBM vs ISBM

Bottle-shaped containers are molded by 3 processes: EBM (extrusion blow molding), IBM (injection blow molding) and ISBM (injection stretch blow molding). EBM is the oldest and least sophisticated of these processes. The following is a list of benefits and problems associated with ISBM and IBM produced bottles. Many users mix up Injection Stretch Blow Molding […]

Increasing Mold Life in 8 ways

COPAR always believes that tool life (mold) is the key to a company’s bottom line and profitability. With the design and building stages complete, it is time to set the mold in the press and develop a process. Here are key press settings and essential preventative maintenance steps to improve mold life. 1- Tonnage Verify […]

How Everything Starts!?

Did you know? Jons Jacob Berzelius produces in 1847 first condensation polymer : polyester, derived from glycerin (propanetriol) and tartaric acid. Berzelius is also credited coining the chemical terms allotrope, catalysis, isomer and polymer. In 1865 Alexander Parkes was the first man made plastic by dissolving cellulose nitrate in alcohol and camphor containing ether. Resulting […]

In Mold Closing System “IMC”

In Mold Closing systems are used to automatically assemble molded parts prior to ejection from the molding surface. These systems operate during the opening time of the mold to minimize the impact on cycle time. Copar uses proprietary, proven IMC designs to integrate the closing rack and maximize mold cavitation. The closing arms provide precise movement […]

PROPAKAFRICA 2019