EXTRUSION

BLOW MOLDS

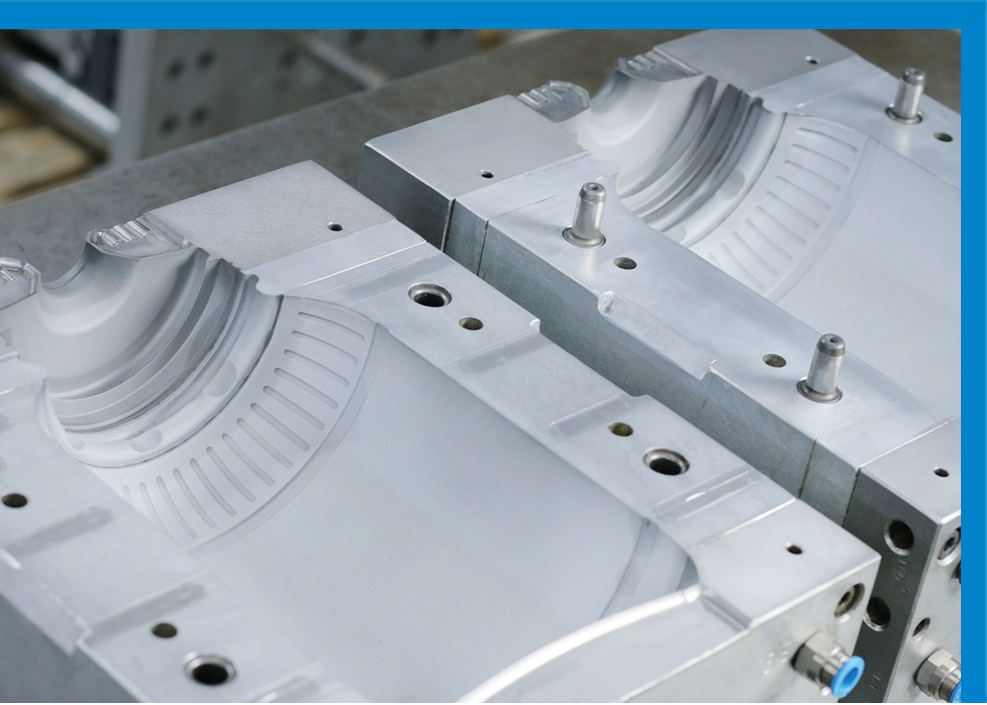

We design and manufacture extrusion blow molds by using the latest technology. Whether you need a single-cavity prototype or a high-volume production mold, our custom molds are created in compliance with the highest standards of excellence, perfectly aligning with your product specifications.

HOW EXTRUSION

BLOW MOLDING

WORKS

Extrusion blow molding is a technique in which a

tube of molten plastic material, called a parison, is

extruded through an extrusion die and then inflated using

compressed air to form a hollow part or container.

Molding Technologies

Beryllium copper insert molds

Beryllium copper insert mold technology uses prefabricated components that are placed into the mold cavity before the injection molding process. The molten material is then injected around and over the inserts, effectively encapsulating them within the final molded part.

Hydraulic movement molds

Hydraulic movement molds involve incorporating hydraulic mechanisms within the mold to facilitate movement during the injection molding process. This innovative approach adds a dynamic element to the molding process, allowing for the creation of complex parts.

Conformal cooling molds

Conformal cooling mold technology focuses on creating mold cavities with cooling channels that closely follow the contours of the molded part. This technique aims to enhance the efficiency and quality of the molding process by optimizing the cooling stage, achieving consistent part quality and minimizing cycle times.