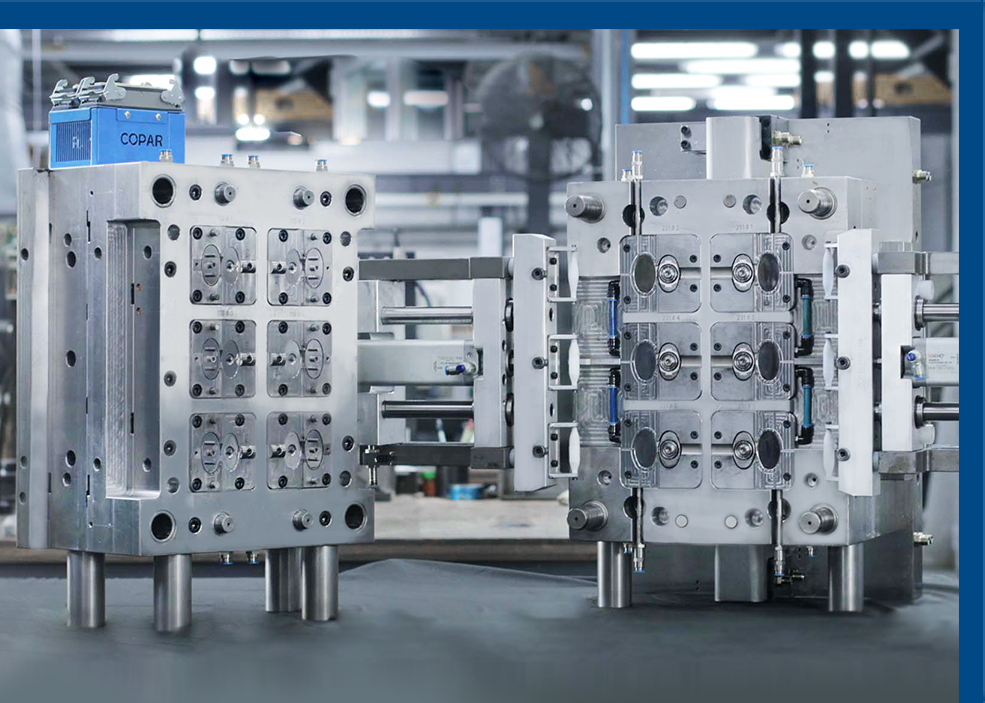

Precision Injection Molds for High-Performance Manufacturing

At COPAR, we design and manufacture high-precision injection molds that meet the demanding needs of industries such as cosmetics, medical, food and beverage, and household products. Using advanced CAD/CAM software and top-grade materials, we ensure each mold delivers consistent, accurate, and long-lasting results. Our injection molds are custom-built to optimize cycle times, reduce waste, and maintain dimensional accuracy across high-volume production runs. Whether for complex parts or simple components, COPAR provides injection molding solutions engineered for efficiency, reliability, and superior product quality.

HOW INJECTION MOLDING WORKS

Injection molding is a high-precision manufacturing process used to produce plastic parts in large volumes with consistent quality. At COPAR, we use this advanced technique to create custom molds that support complex shapes and detailed designs across various industries.

The process begins with melting plastic resin and injecting it into a precision-engineered mold cavity under high pressure. Once the material cools and solidifies, the part is ejected, resulting in a durable, accurately shaped product. This method ensures high efficiency, minimal waste, and excellent repeatability—making it ideal for mass production.

With years of experience and cutting-edge equipment, COPAR delivers injection molding solutions that meet the highest standards of performance and reliability.