Nine Questions Every Client Should Ask Before Selecting a Mold Maker Partner

Selecting the right mold maker partner is a critical step in ensuring the success of your manufacturing project. A trusted partner can help you save costs, reduce lead times, and ensure product quality. On the other hand, choosing the wrong partner can lead to expensive delays, poor-quality molds, and wasted resources. To guide your selection […]

Mold Trial Production Operational Manual

In the world of plastic manufacturing, the mold trial phase is a critical step in ensuring production success. A well-executed mold trial helps identify defects, evaluate performance, and confirm that the mold meets design specifications before mass production. This manual provides a step-by-step guide for running efficient mold trials, minimizing risk, and maximizing mold life. […]

IBM vs ISBM: A Comprehensive Guide to Injection Molding Techniques

In the world of plastic manufacturing, two common techniques used for producing bottles and containers are Injection Blow Molding (IBM) and Injection Stretch Blow Molding (ISBM). While both processes share similarities, they have distinct advantages and are suited for different applications. Understanding the differences between IBM and ISBM is crucial for manufacturers and businesses to […]

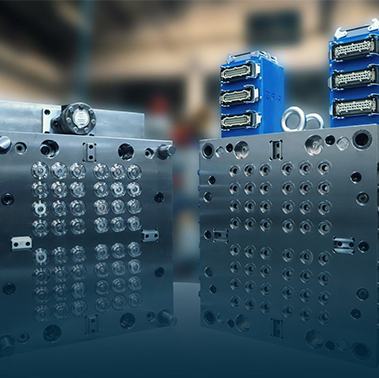

8 Proven Ways to Increase Mold Life and Reduce Production Costs

In the world of plastic manufacturing, mold life directly impacts productivity, cost-efficiency, and overall product quality. A longer-lasting mold means fewer replacements, less downtime, and better return on investment. But how exactly can you increase mold life? From materials to maintenance, this guide explores eight actionable strategies manufacturers can implement to significantly extend the lifespan […]

In-Mold Closing System (IMC): How It Enhances Plastic Packaging Efficiency

I In-Mold Closing System (IMC): How It Enhances Plastic Packaging Efficiency In-Mold Closing System (IMC): How It Enhances Plastic Packaging Efficiency In-Mold Closing System (IMC): How It Enhances Plastic Packaging Efficiency In Mold Closing systems are used to automatically assemble molded parts prior to ejection from the molding surface. These systems operate during the opening time […]

K2022.. MEET US IN DUSSELDORF –GERMANY FROM 19 TILL 16 OCTOBER AT HALL 1 – A91